BLOG

KATEGORİDEKİ DİĞER YAZILAR

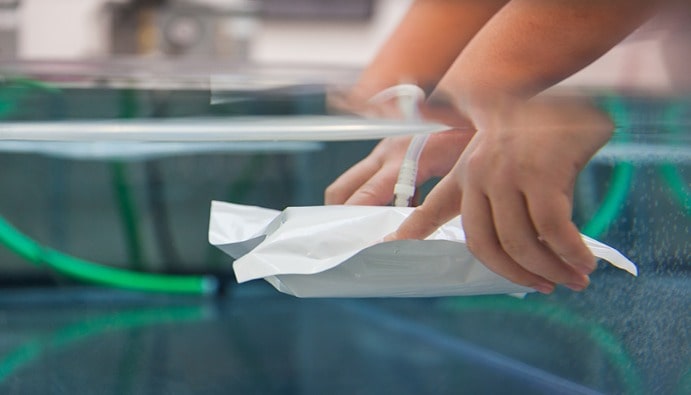

Leak testing with bubble emissions is a standard test method for identifying large leaks in flexible packaging containing bubble emission and headspace gas.

The test is performed by immersing the packages in water in the vacuum chamber. If bubbles or leakage of liquid are observed in the sample, which can be attributed to a leak, the sample will not pass the test.

Testing is carried out in a vacuum chamber with a vacuum-tight cover and resistant to approximately one atmosphere. In general, immersion liquids that do not spoil the packaging package are used in test processes.

| ASTM D3078 | Standard Test Method for Determining Leaks in Flexible Packaging with Bubble Emission |

| ASTM F2029 | Standard Test Method for Detection of Gross Leakage in Medical Packages by Internal Pressurization (Bubble Test) |