Flexible Packaging Testing Methods for Reliable Packaging

Flexible Packaging Testing Methods for Reliable Packaging

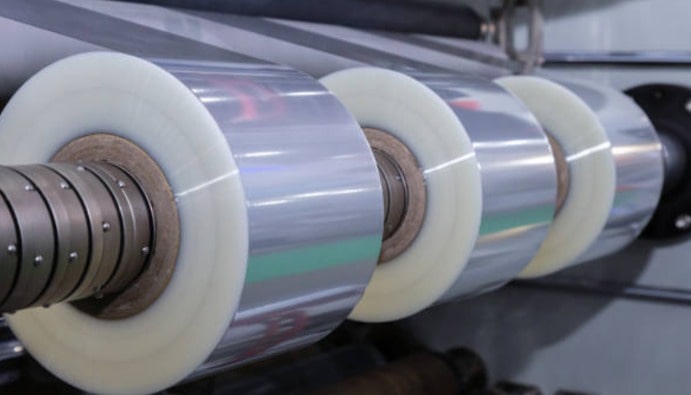

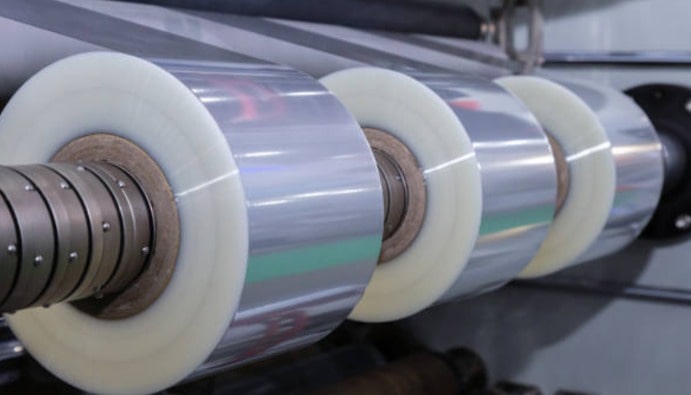

When a new package is developed, it must pass various tests in order to be resistant to all conditions. The outer packaging usually has to withstand a great deal of physical and mechanical stress. The testing procedures required for film and flexible packaging differ from those required for rigid packaging. In flexible packaging materials, necessary test and analysis studies are also required, such as flexing and cracking resistance, impermeability, barrier properties.

Physical, chemical and mechanical tests performed on flexible packaging materials can be listed as follows:

1. Dimension Testing

Size test: It is the test method performed to determine the size of the package before and after it is filled. Flexible packaging changes shape according to content. That's why it's important to check for length, width and depth when full and empty. The size test also includes the weight test of the flexible packaging. It is measured in grams of GSM per square meter as part of the weight test. GSM value is inversely proportional to efficiency.

2.Testing for Mechanical properties

Mechanical tests include checking the determination of the resistance of flexible packaging to physical and mechanical stress.

- Tensile StrengthIt is carried out to determine how much force is required for breaking – breaking in flexible packages and how long it can stretch before breaking – breaking.

- Dart Impact TestingDart impact test checks the durability of flexible packages by dropping darts of different weights from a certain height.

- Bond Strength (PET, Poly)Flexible packaging materials often contain multiple layers of polymers, including metallized sheets. The bond strength test checks how much force is required to separate the layers.

- Seam StrengthSeam strength controls the strength of the package in areas where two films or sheets are joined.

- Flex Crack Resistance (FCR)It is performed to determine how fragile the flexible packaging is. The test method aims to determine how much the packaging material can bend without breaking.

- The Coefficient of Friction (CoF)CoF controls how easily two surfaces slide against each other. It provides control of how smooth the packaging or film is. It gives an idea of how easily packaging films can slide over another material during packaging.

3. Testing of Functional Properties

The functional properties of flexible packaging include its dissolution, diffusion and adsorption.

- Water Vapor Transmission Rate (WVTR)Water vapor permeability of the material at a selected temperature, pressure and humidity. checks. Transmission rate is measured in grams per square meter per day.

- Oxygen Transmission Rate (OTR)Cut the packaging film to create a barrier between an oxygen-free and oxygen-filled room. uses. Like the WVTR test, it is measured in moles per square meter per day.

4. Packaging Strength and Integrity Tests

- Seal Strength TestIt is performed to determine how strong the seal is in flexible packages and how long it keeps the package closed over time.

- Drop Test

Checks whether the flexible packaging is resistant to drops when filled. In order to pass the drop test, the materials used in the construction of the package and the seal must not be damaged.

- Vibration Test

Checks how long the package can withstand vibrations.

- Compatibility Test

Compatibility tests are very important in terms of understanding the shelf life of the product in its package. This flexible packaging test checks whether the product inside is compatible with the materials used to make the packaging and the sealing method.

- Scuff Proofness

The test that checks the resistance of the packaging against scratches

- Leakage Test

Leakage tests check whether the joints, seals or materials of the package are leaking by placing the package filled with the product in a vacuum chamber.

- Global Migration

The migration test evaluates the toxicological risks associated with the packaging. It is carried out to determine the transition of toxic chemicals in flexible packages to foods.

- Environmental Stress Crack Resistance (ESCR)

ESCR is how much the package resists Environmental stress cracking or ESC. Checks for resistance. ESC is quite common in plastics as they become brittle over time through exposure to UV and reacting with other reagents.

5. Visibility and Appearance Test

- Color Fastness

Color fastness is tested by exposing the package to substances that can cause discoloration.

- Haze and Gloss

Turbidity is tested using a Spectrophotometer while gloss is tested using a Glossmeter.