BLOG

KATEGORİDEKİ DİĞER YAZILAR

Mullen Burst Testing is a test method for measuring the bursting strength of paper and cardboard. Mullen Burst Testing is placed between two ring-like clamps on the special testing device. While the sample is in the instrument, it begins to apply hydraulic pressure to inflate a rubber diaphragm that will stretch the sample. The measure of the total hydraulic pressure obtained at the breaking point of the sample is defined as the bursting force of the sample.

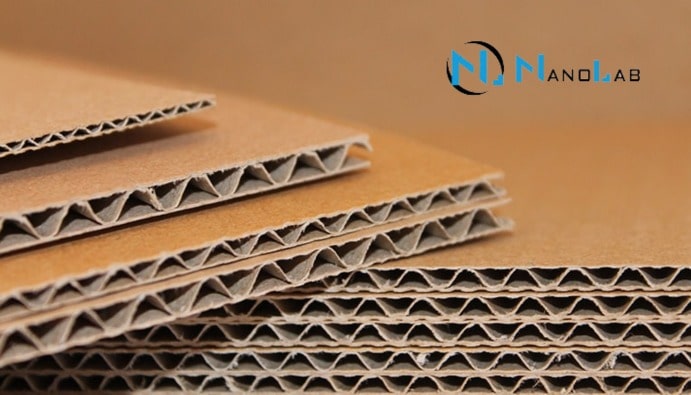

Mullen Burst Testing is performed on paper and cardboard samples from which products such as packaging and envelopes are produced. It is carried out within the scope of the “TAPPI T 810: Bursting strength of corrugated cardboard” standard.

The bursting power of corrugated cardboard to be used in packaging is related to its durability against transportation and storage conditions. The material to be used is decided by determining the important details such as the weight that the packaging can carry and the ability to protect the products inside.

You can contact Nanolab Packaging Analysis Laboratory for Mullen Burst Testing.